Basic Technical Training

¿Quieres trabajar en el sector eólico? Entonces necesitas el curso BTT – Basic Technical Training de GWO.

El curso oficial de la GWO para trabajos técnicos en aerogeneradores (BTT) está diseñado para personas sin experiencia previa en sistemas hidráulicos, mecánicos o eléctricos. Sin embargo, las personas con experiencia en estos campos pueden actualizar y aumentar sus conocimientos en estas áreas, especialmente en lo aplicable a los aerogeneradores.

El curso de BTT – Basic Technical Training (Formación Técnica Básica) consta de cinco módulos diferentes dedicados a cada uno de los sistemas técnicos empleados en aerogeneradores.

- Modulo Mecánica.

- Módulo Electricidad.

- Módulo Hidráulica.

- Módulo Instalación.

- Módulo Apriete de pernos.

La validez de los certificados BTT es permanente. Al finalizar el curso, los participantes estarán familiarizados con los sistemas hidráulicos, mecánicos y eléctricos de los aerogeneradores y podrán trabajar en la industria eólica tanto onshore como en offshore.

Para hacer el curso, tienes que:

- tener al menos 18 años

- estar en buena forma física y mental

El curso dura 54 horas (siete días y medio) y se hace en centros de formación acreditados por GWO.

Al terminar el curso, recibirás un certificado de validez permanente y que te permite trabajar en cualquier instalación eólica que siga el estándar GWO.

Basic Technical Training – Mecánica

BTT Mecánica

BTTM

El curso de BTT Mecánica forma parte de BTT – Basic Technical Training y te proporciona los conocimientos y habilidades para llevar a cabo tareas mecánicas básicas, supervisadas por un técnico experimentado, utilizando los procedimientos de trabajo seguros y los Equipos de Protección Individual (EPI) adecuados.

El curso tiene una duración de 9 horas (un día y medio) y te otorga una certificación oficial con validez permanente.

El módulo de BTT Mecánica te prepara para que puedas:

- Explicar los componentes principales, los sistemas mecánicos y el funcionamiento básico de las turbinas eólicas.

- Explicar los riesgos y peligros asociados con la mecánica.

- Comprender los principios de las conexiones atornilladas y soldadas y su inspección.

- Demostrar habilidades prácticas para usar herramientas manuales de apriete y medición.

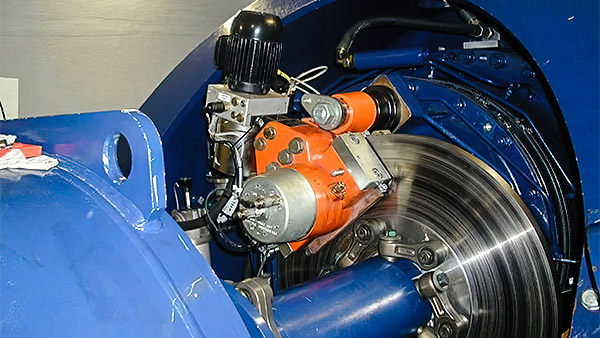

- Demuestre el uso correcto de torque hidráulico y herramientas de tensión.

- Explicar los principios de una caja de cambios.

- Explicar la función de los sistemas de frenos y demostrar cómo inspeccionarlos.

- Explicar la función del sistema de guiñada y explicar cómo inspeccionarlo.

- Explicar la función del sistema de enfriamiento y demostrar cómo inspeccionarlo.

- Explicar la función del sistema de lubricación y demostrar cómo inspeccionarlo.

Basic Technical Training – Electricidad

BTT Electricidad

BTTE

El curso de BTT Electricidad forma parte de BTT – Basic Technical Training y te proporciona los conocimientos y habilidades para llevar a cabo tareas eléctricas básicas entorno de los aerogeneradores, supervisadas por un técnico experimentado, utilizando procedimientos de trabajo seguros y los Equipos de Protección Individual (EPI) adecuados.

El curso tiene una duración de 10 horas (un día y medio) y te otorga una certificación oficial con validez permanente.

El módulo de BTT Electricidad te prepara para que puedas:

- Explicar los conceptos básicos de la electricidad.

- Explicar los riesgos y peligros asociados con el trabajo eléctrico.

- Explicar la función y el símbolo de los componentes eléctricos.

- Explicar la función de diferentes tipos de sensores.

- Explicar e interpretar un diagrama eléctrico simple y demostrar cómo ensamblarlo en un circuito.

- Demostrar cómo hacer mediciones correctas y seguras.

Basic Technical Training – Hidráulica

BTT Hidráulica

BTTH

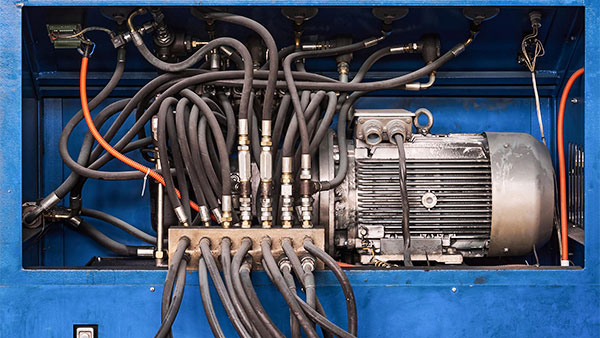

El curso de BTT Hidráulica forma parte de BTT – Basic Technical Training y te proporciona los conocimientos y habilidades para llevar a cabo tareas hidráulicas básicas supervisadas por un técnico experimentado, utilizando procedimientos de trabajo seguros y los Equipos de Protección Individual (EPI) adecuados.

El curso tiene una duración de 9 horas (un día y medio) y te otorga una certificación oficial con validez permanente.

El módulo de BTT Hidráulica te prepara para que puedas:

- Explicar los conceptos básicos de la hidráulica.

- Explicar los riesgos y peligros asociados con el trabajo hidráulico.

- Explicar la función de los diferentes tipos de bombas y demostrar cómo verificar la presión de arranque / parada de una bomba.

- Explicar la función de los diferentes tipos de actuadores.

- Explicar la función de diferentes tipos de válvulas.

- Explicar la función de los acumuladores y demostrar cómo verificarlos y precargarlos.

- Explicar la función de diferentes tipos de sensores.

- Identificar los componentes que transfieren el aceite.

- Describir el manejo de los procedimientos de aceite.

- Identificar y encontrar diferentes componentes en un diagrama hidráulico.

- Demostrar cómo medir la presión hidráulica con precisión.

Basic Technical Training – Instalación

BTT Instalación

BTTI

El curso de BTT Instalación forma parte de BTT – Basic Technical Training y proporciona los conocimientos y habilidades para llevar a cabo tareas básicas en la instalación de aerogeneradores, supervisadas por un técnico experimentado, y utilizando procedimientos de trabajo seguros y el Equipos de Protección Individual (EPI) adecuados.

El curso tiene una duración de 18 horas (dos días y medio) y te otorga una certificación oficial con validez permanente.

El módulo de BTT Instalación te prepara para que puedas:

- Identificar las actividades principales de instalación y explicar los riesgos y riesgos generales asociados con el entorno de instalación.

- Explicar el sistema de lista de verificación a lo largo de todo el proceso de instalación.

- Explicar las características del entorno de instalación.

- Explicar los principios y estándares para manejar y almacenar bienes y componentes en el sitio o dentro de un área de almacenamiento antes y después de la instalación.

- Explicar los principios básicos del equipo de elevación.

- Explicar la preparación básica de los componentes principales antes de la instalación.

- Explicar la terminación mecánica básica.

- Demostrar cómo realizar la terminación eléctrica básica, incluidos los principios y estándares para el manejo e instalación de cables.

- Explicar la terminación hidráulica básica.

- Explicar los principios de operación de generadores externos durante la instalación.

- Explicar la base de cómo hacer una transferencia a la puesta en marcha.

Basic Technical Training – Apriete de pernos

BTT Apriete de pernos

BTTB

El curso de BTT Apriete de pernos forma parte de BTT – Basic Technical Training y proporciona los conocimientos y habilidades para planificar, llevar a cabo y completar tareas genéricas de apriete y tensado de pernos según las especificaciones utilizando equipos alimentados por energía de manera segura.

El curso tiene una duración de 8 horas (un día) y te otorga una certificación oficial con validez permanente.

El módulo de BTT Apriete de pernos te prepara para que puedas:

- Planificar y prepararse para completar de manera segura y correcta tareas de apriete de tornillos según las especificaciones.

- Llevar a cabo de manera segura y correcta tareas de apriete de tornillos según las especificaciones utilizando equipos de apriete eléctricos e hidráulicos.

- Llevar a cabo de manera segura y correcta tareas de apriete de tornillos según las especificaciones utilizando una combinación de equipos de apriete eléctricos e hidráulicos.

- Llevar a cabo de manera segura y correcta tareas de tensado de tornillos de 2 etapas según las especificaciones utilizando equipos de tensado hidráulico.

- Llevar a cabo de manera segura y correcta tareas de tensado de tornillos según las especificaciones utilizando una combinación de equipos de apriete eléctricos e hidráulicos.

Dónde estamos

Polígono Industrial Matallón Parcela 12 Calle B, 9B, 31579 Cárcar, Navarra

Teléfono

(+34) 664 68 13 85

info@totalhse.com